India’s industrial landscape is changing. Smokestacks, while once the harbinger of industrial success, today it is smart systems and green sensors that mark industry progress. Industry 4.0, the convergence of digital, physical, and biological technologies, is not just revolutionizing manufacturing; it is sparking an eco-industrial renaissance. Going forward, this change cannot be undermined and will impact all platforms manufacturing, whether it is big, small or medium units.

The Great Indian Paradox: Growth versus Green

India’s Manufacturing sector has emerged with a GDP contribution of 17% and is rising as a global player, comprehending diversity and complexity. Equally, as a country, it has struggled for decades over a paradigm problem: how to industrialise quickly, yet keep environmental damage to a minimum. Conventional production models, emissions, high carbon footprints, waste generation, air and water pollution are major concerns for the country. That is where Industry 4.0 comes in: no silver bullet, but an effective array of technologies to reconcile and create balance.

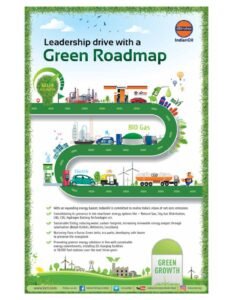

Technologies such as Internet of Things, AI, and robotics enable factories to decrease their energy usage, anticipate maintenance, optimize production processes, and eliminate waste, all while improving profitability. Sustainability and smart manufacturing convergence are not just a trend, but a necessity.

Jugaad to Juggernaut: India’s Industry 4.0 Journey

India’s innovation ethos has traditionally been characterized by ‘jugaad’ – resourceful, often low-cost improvisation. Now, that tradition is gaining high-tech form. Pune, Bengaluru, and Chennai factories are embracing green automation and cyber-physical systems to not just keep up with the world but lead it with the principles of sustainability.

Consider the automobile industry, for example: Tata Motors and Mahindra have coupled sophisticated analytics to reduce waste and emissions. Pharmaceutical companies such as Cipla utilize data-driven modelling to curtail energy consumption in delicate production environments.

A Sustainable Business Case (Not Simply A Moral One)

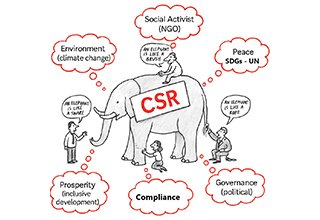

Let there be no confusion: to be green is no longer good PR, it is good business. Carbon accountability is now the expectation across global supply chains. ESG (Environmental, Social, and Governance) data drives capital flows. Consumers prefer to pay more for ethically sourced goods. Industry 4.0 enables Indian factories to fulfil these expectations without sacrificing efficiency.

For instance, smart grid-based real-time energy monitoring enables businesses to reschedule loads and lower electricity bills. Predictive maintenance prolongs equipment life and cuts downtimes. Raw materials usage is cut by up to 80% through 3D printing. They are not just environmental gains; they are bottom-line gains.

Roadblocks on the Runway

However, such a green revolution is not without turbulence. Sunk costs, lack of skilled labour, cybersecurity issues, and fragmentary policy backing still inhibit widespread adoption. In addition, India’s continued dependence on coal-intensive electricity compromises the environmental pay-offs from even the most technologically sophisticated gadgets.

But where the discussion needs to mature is to move beyond waiting for ideal conditions to act. Pilot projects, public-private initiatives, and skill-development missions can achieve stepwise adoption. Industry 4.0 is not an endpoint, it is an ongoing, dynamic process. It is an ongoing journey of innovation, where technology evolves alongside efforts to find solutions to environmental challenges

The Role of the Government: Catalyst, Not Controller

India needs to change its policy paradigm to be more incentive-based, not compliance-based. Make in India can be turbocharged through tax incentives for green tech adoption, rapid approval for smart factories, and grants for research and development towards solutions for sustainability. More critically, environmental regulations must reward, and not simply penalize, good performance.

The National Manufacturing Policy must be overhauled immediately to adopt digital-ecological metrics. State governments, usually the actual implementors, must become proactive partners in supporting decentralized smart manufacturing clusters.

The Future is Hybrid, Holistic, and Human-Centric

The future leap will be marked by hybrid models: the partnership of human creativity and machine precision, centralized digital command centers and localized green values, and scalable technologies and bottom-up implementation. Envision solar-powered factories based on AI-optimized systems, where artisans and robots codevelop export-quality products.

This is not science fiction. It is already underway, quietly, in isolated places. India has the potential to take these mini-successes to macro-changes.

Last Word: From Imitation to Innovation

India does not have to follow or learn from the West’s industrial experience. Our own culture has evolved from the human values that have venerated all the five elements. We can leapfrog. Embedding environmental sustainability in the DNA of smart manufacturing can help not only decarbonize India’s growth trajectory but also provide a model for the Global South as well. Let us not present Industry 4.0 as an upgrade in technology. Let us look at it for what it is, really, an economic, moral, and environmental imperative. Within this confluence of smart and sustainable is the industrial destiny of India.

The author of the article is Head – Karma Yoga, Area of Expertise: Sustainable Livelihoods, Cross-Cultural Management, Inter Cultural Communication, Conflict Management and Development Communication Models for Sustainable Development, Great Lakes Institute of Management, Chennai.